“Just to meet business-as-usual trends, 115% more copper must be mined in the next 30 years than has been mined historically until now,” the study said.

Its almost like the answer isn’t some whimsical butler just for you, but fucking public transportation. Build fucking trains.

Agreed. I love trains and it frustrates me to see them bungling the implementation. When they try, they always seem to make the same mistakes trying to bring it to my area.

To see meaningful ridership out here, the train needs to go fast enough to negate the penalty you get at the other end when you have to go from the station to your destination. They wanted to run them at ~55-70mph here, with a few stops between major cities, to parallel a freeway that is 65-75mph. Drive 1 hour (1:10 with parking) or spend 2 hours going to the station, riding a slow train, then going from the station to where you are going? I hate cars, but as someone who only gets a handful of hours to myself after sleep, work, and chores, I’m going to save my time and pick the car. If they ever build the train, as it is planned right now, it’ll just be another commuter train that’s only really used at rush hour when the roads are jammed rather than an all day all week car replacement solution that I can ride to Sunday night dinner at a friends house as easily as a 6am meeting.

/un-requested rant

@njordomir @Sanctus The safe money is it will also run too infrequently to be a good replacement. Adding ‘time waiting for train’ to the picture for trips outside of 6~9am or 3~7pm and officials wonder why services aren’t well used.

Interestingly, a similar problem as with bike infrastructure. The infrastructure isn’t useful until a lot of it is built and it connects everywhere (and timetables get shorter for trains). The infrastructure won’t pass public opinion until it’s proven to be useful to people. I will always vote yes on funding these projects even if I think they will bomb because it puts us a little closer to the peak of that hill. Its still frustrating though. We could easily do like we did with the freeways if we just decided it was worth building.

@njordomir But all of it is network effect in action: the incremental value of each piece is related to how many pieces already exist.

The worse part is, what infrastructure does get built isn’t used because it’s mostly useless, and people use this lack of use as justification for not building more.

My current push is bike infra for kids to get to school, parks, community centers and libraries. Roads aren’t a safe for them and they can’t drive themselves.

My city has been pushing through improving the biking infrastructure for a decade now.

People have been bitching about it from day one. They bitched even more as the first lanes were going in, as they were “useless” and went “nowhere”

They’ve continued to bitch about it every year, every construction project.

But now, we have a highly interconnected network of bike lanes (most protected) all around town and they’re getting heavily used.

People still find reasons to bitch about it like it’s slowing down traffic by narrowing roads or lost parking spots or whatever, but the “it’s not useful” stuff has stopped.

Trams are the future!

Maybe build ebikes instead of EVs? Then you’d need about 1/50th to 1/100th the copper.

Yes, and also build trains instead of EVs

Trains don’t even need batteries

Don’t forget tramlines.

Metal Theft sector booming. Meth stocks are up.

They’ll start mining landfill for metals and probably plastic soon enough. Air it out, wash it, get the metal and plastic, don’t worry about that other in the air/water, that’s a future poor person’s problem.

metals, sure. The problem with plastics is that plastic is not plastic, it’s a plethora of different chemical structures. Very difficult to recycle some of them, even if sorted.

“Recycling the plastic” in my tip-mine dystopia fantasy would be what they called burning plastic to fire the smelt to get the metals out. They’re gonna burn rubbish for metal and market it as a good thing, someone will get paid a lot of money to think of a word like reclamation.

If it’s incinerated properly, burning the old plastic shouldn’t be much different from burning other hydrocarbons.

I’d rather they burned up plastics from landfills than coal, and probably oil and gas too really.

So it’s time to a coup d’etat on Chile AGAIN!

Or more child slavery, maybe? Sorry, that is for batteries.

for god “Capital”

I always find it ironic that people with the most money are always the hungriest for it. Their entire lives revolve around it, and they are willing to pay any other price for it. They will kill ecosystems, pollute everything and even destroy societies for it.

Power does not corrupt, it only attracts the corrupted

No one uses pennies anymore… Just sayin’.

If I’m reading this chart correctly, each penny is only 2.5% copper.

This can be improved if all vehicles moved to a full 48v architecture. Substantially less copper that way.

@NotMyOldRedditName @Hypx I’m not against it, but I didn’t think most of the copper in a modern car / EV was in the LV supply wiring, so such a change would be more in the range of a 10% reduction?

It’s somewhere between 100 and 150lbs saved per car.

There’s a lot of copper in the wiring harness and it’s most of the weight. It’s also a reduction in the plastic around the wires, the other weight contributor.

Edit: For EVs anyway, my bad. Probably less copper in non evs, but still a lot.

@NotMyOldRedditName Are power carrying wires the bulk of the wires in a car?

And by power I mean more than 5W where wire gauges start to get serious at 12V. An indicator LED is technically needing power, but not enough that wire gauge bulks up.

Wiring harnesses from traditional automotive companies are quite long. This is quote from Ford’s CEO

““We didn’t know that our wiring harness for Mach-E was 1.6 kilometers longer than it needed to be. We didn’t know it’s 70 pounds heavier and that that’s [cost an extra] $300 a battery,””

4km is normal

https://q5d.com/escalating-function-dilemma/

"Some modern vehicles contain close to 40 different harnesses, comprised of roughly 700 connectors and over 3000 wires. If taken apart and put into a continuous line, these wires would exceed a length of 2.5mi (4km) and weigh approximately 132lbs (60kg). Five years ago, vehicles had 25% less circuits than today’s cars. Five years from now, that number will increase by more than 30%. "

@NotMyOldRedditName yes, but that is tangential to my point (and your original point). The total length of wires doesn’t tell you if they are power or data.

Fair, but you can’t do 12v ethernet like they’ve done with 48v. The cables would be too big

So unlocking 48v allowed the change which allowed lesser cabling.

Tesla claims it’s 77% cable reduction and 50% copper.

Edit: also Teslas wiring harnesses have been smaller than industry standard for years. If others made the switch and moved to an etherloop as well, the copper savings would be even bigger than what Tesla experienced.

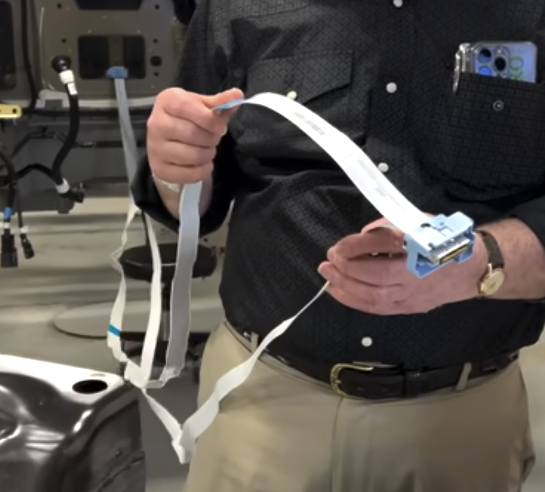

Also just for reference, this is what Tesla’s double redundant 48v etherloop cable looks like, instead of those chonky wiring harnesses

Edit: Just to clarify here, I think I made an assumption about the double redundancy. The cable runs in a loop around the car, and if any cable gets cut, it can still reach the component via the other direction (A<->B<->C<->A). I think I just assumed the 2 wires in the image were redundant. It could be that different data is flowing over both strands and those are not for redundancy. Maybe those are for each direction as well? One cable sends data around the car clockwise, the other counter clockwise?

Deploy the crackheads!

deleted by creator

deleted by creator

deleted by creator

Use Aluminum! There’s nothing about copper that at this point aluminum couldn’t really do.

Tell me you don’t know metallurgy without telling me…

Give me an example where you think you got the upper hand on aluminum knowledge. LOL. Yeah it’s harder to work with. But it’s lighter and metallurgy has very little to do with the reasons why it’s not used. I’ll wait here while you go scrambling through Google’s shitty results.

I don’t have to, its electrical and thermal properties are trash compared to copper. There’s a reason copper is used EVERYWHERE it matters by electrical engineers. I trust them :)

I also almost forgot about our good friend Carbon.

https://www.frontiersin.org/articles/10.3389/fmats.2020.00219/full

Yeah it’s properties are also shit.

But you also should know that motors are controlled with high frequency voltages. That sort of RF actually travels down the material’s skin rather than through the core. This Aluminum, being lighter, can also be made to have a larger surface area. You would get a kick if you knew what I do for work and fun.

Aluminum coil transformers produce more waste heat and are more susceptible to vibration than copper coil.

Ev motors are big coils.

It’s gotta be copper.

As an example:

By weight (mass) aluminum is about twice as good a conductor as copper. This is important when they are hanging high-voltage wires from towers

Not my words. You’re wrong. The problem is 1) enamel coating research. 2) the strength of the material. Aluminum that is formable into wire is just darn soft and can easily fracture from bending. 3) I would say is the issue with not being able to solder to it. It has to be crimped connections which may fail due to corrosion. But all these are fixable problems. Aluminum is a conductor that is on par with copper for usability, and it is way more abundant.

I mean, you’re right, but we can’t use braided aluminum wire to make the coils in transformers and motors, so aluminums greater conductivity by mass is undercut by not being able to take advantage of that property because the engineering for motors and transformers dictates solid wire of a specific diameter.

Also an aluminum winding transformer or motor needs a bigger slug to deal with the more than double resistivity and at some point the benefits of aluminums cheapness and lightness disappear when you gotta have more heavy iron in the core, more heat and more winding failure due to vibration.

I don’t think that means we’re not gonna see ev motors with aluminum windings, just that they’ll be in shitty cheap vehicles for poor people.

And it is being tried right now: https://www.electricmotorengineering.com/aluminium-windings/

Some of the stuff about that company says it’s doing aluminum windings and some of it says they’re doing no windings with flux barriers and air gaps. What’s up with that, different experimental technologies?

I’m skeptical of their claims about it being environmentally friendly since more stuff made out of aluminum means more aluminum being pulled out of the ground, but it’ll be interesting to see that develop.

E: their claim that it’s environmentally friendly because it’s got less rare earths makes sense now because they gotta use iron instead cause of the resistivity. I’m genuinely interested to see how much weight or volume savings they get and the efficiency for a given power output compared to a traditional copper and rare earth motor.

It really seems like a strange step backwards (not an insult, plenty of old technologies are perfectly valid and their manufacturing techniques need to still exist) to get cheaper components that sidestep the cost of shipping recycled copper around.

At some point the high cost of recycled materials has to be integrated into the supply chain somehow otherwise the benefit of having recycled them will never be realized. This technology seems like a scheme to increase consumption without dealing with the consequences of previous consumption.

Either way they’d have to rip out new ore, probably burning carbon to dig it up. Then smelt it, using more carbon, then transport the metal and turn it into an EV. Seems like developing more effecient forms of transportation would be a lot more green than selling everyone a new “green” electric vehicle.

Agreed. Fuck cars. But if you just gotta have that big monster truck, go with aluminum core motors. Less mass means more acceleration. There’s less inertia.

aluminum is only 61% as conductive as copper, but it weighs 2x less. it is used in overhead high voltage cable.